Power transformers can last anywhere from 15-30 years, but when they enter the end of their life cycle and suddenly self-destruct, plant managers are left scrambling to find a replacement. While under the gun, the scramble to source a duplicate from the exact same manufacturer often seems like the only solution, there are other options. The availability of transformer manufacturers that specialize in customizing the transformers they carry in stock to match an end-user’s setup saves time and money, while greatly reducing downtime and the associated headaches.

Last summer, the CertainTeed plant in L’Anse, Michigan, encountered this exact issue. They had a turn-to-turn short in the 1000 KVA transformer running their manufacturing floor. “It ended up being a total failure, so production went down immediately,” recalls Logan Edwards, an electrical engineer for the building products producer.

CertainTeed is manufacturer of exterior and interior building products, including roofing, siding, fences, decking, railing, trim, insulation, gypsum and ceilings.

“We could not afford to halt production, so I rented an 1000 KVA generator to hold us until we could get a replacement transformer,” continues Edwards. “But the monthly rental fee for the generator was extremely expensive – approaching five figures. Plus, the fuel required to run it was costing thousands of dollars. So, we needed a transformer, fast!”

Finding like for like, in a hurry – In search of not only a fast and perfect fit – along with original quality of construction – plant engineers often assume that they can still get the same exact replacement from the same exact manufacturer.

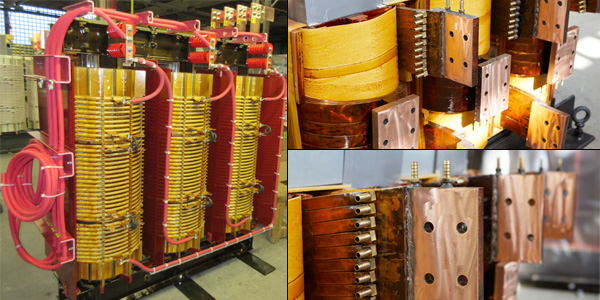

“The reality is that many of the original manufacturers went out of business long ago or were bought out,” observes Alan Ober, an engineering manager at ELSCO (www.elscotransformers.com) a Cincinnati-based transformer manufacturer providing new, repaired and rebuilt transformers ranging from 500 through 3750 KVA in 2.5, 5 and 15KV primary voltages. “For instance, GE Industrial, Square D, Schneider and a lot of others are either no longer in business or are part of other companies now.”

Yet, some plant engineers have discovered a way around the “exact replacement vs. quick replacement” dilemma in the form of vendors who specialize in repairing original transformers, or building new transformers with quality materials, in advance.

Once completed, both remanufactured and new transformers are stocked in a warehouse. When an engineer calls up for an emergency replacement, the transformer is pulled out of storage, custom bus work is machined to the exact specifications of the enclosure, and the transformer is loaded onto a truck. Some manufacturers can do all this in a matter of 24-36 hours.

Much of the credit for such a solution goes to the careful gathering of the dimensions of the transformer, and then duplicating it as precisely as possible. As a result, both the high side and low side line up as in the original installation. The same attention to dimensional detail extends to ensuring the transformer feet fit on the front-to-back runners of the existing enclosure. As a result, the transformer gets energized quickly and the plant resumes full operation with minimal downtime.

For more information, contact: www.electricservice.com.