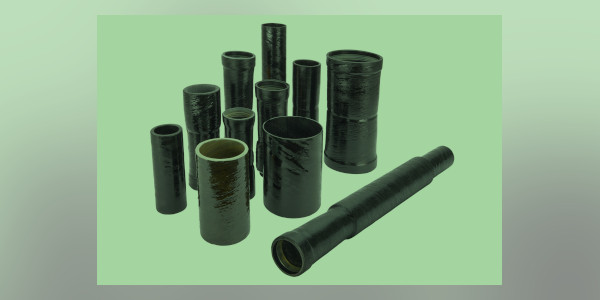

Atkore’s FRE Composites® fiberglass conduit recently experienced increased demand in above- and below-ground applications due to an overall surge in the conduit market. FRE’s is a cost-efficient alternative to traditional PVC conduit, which currently is impacted by material shortages resulting in longer lead times.

Compared to PVC, fiberglass conduit is lighter weight, more durable, easier to install, and competitively priced, which makes fiberglass conduit an ideal substitute on projects where PVC is used.

Fiberglass conduit provides better protection against corrosion, toxicity, and burn throughs when compared to other conduit materials. Fiberglass conduit is suited for temperatures between -40°F and +230°F and has a low coefficient of friction for easier wire-pulling, potentially reducing the frequency and number of manholes. Additionally, on projects involving longer and harder wire pulls, fiberglass elbows reduce or eliminate damage to wires due to costly rope burn-through. Further, FRE Composite’s fiberglass electrical conduit and elbows can be equipped with patented TriSeal® joints, providing a 500-pound pullout strength.

“If your project calls for direct burial or encasing conduit in concrete, fiberglass is the ideal solution,” says Tom Feissle, Director of Business Development for FRE Composites. “Our TriSeal joints eliminate the need for adhesive, significantly reducing installation time.”

FRE Composites epoxy-based conduit is well-suited for underground duct banks like those used for data centers, large infrastructure projects, or any direct burial installation.

For more information, visit frecompositesinc.com.