Simplifying and streamlining upgrades and support for the array of technologies in switch pole to substations

Utilities face an ongoing challenge of orchestrating data acquisition and communications between aging measurement and control equipment across their networks. From switch poles to large scale transmission and distribution stations, the equipment used to monitor and control power delivery across a utility’s network can use multiple communication protocols from different generations. They also vary significantly in age, configurability, performance and complexity.

Today, field engineers must use multiple programming languages simply to maintain and upgrade the wide array of equipment and technologies that have accumulated in a network over the decades. Added challenges include lack of vendor support for older equipment, difficulties in sourcing parts, and lack of compatibility with newer devices and software. Until utilities replace all of their aging Remote Terminal Units (RTUs) and Supervisory Control and Data Acquisition (SCADA) equipment, these challenges will continue to persist.

“What we have currently is a high level of complexity and therefore inefficiency in managing our field equipment,” said a lead measurement controls technician from an electric power company in Kentucky that serves 1.1 million people throughout the state.

Orchestration using a single platform – A solution that the power company has adopted to address their technology management needs is to use a single programming platform that can orchestrate the communications between all the equipment and communications protocols at a location in their network of over 120 transmission and 500 distribution substations.

“Our goal was to find a single platform that will function correctly in all the different equipment we manage,” said the technician. “Our department is responsible for SCADA and metering from transmission to distribution substations, switch poles and everything in between. We have to be able to program all these devices.”

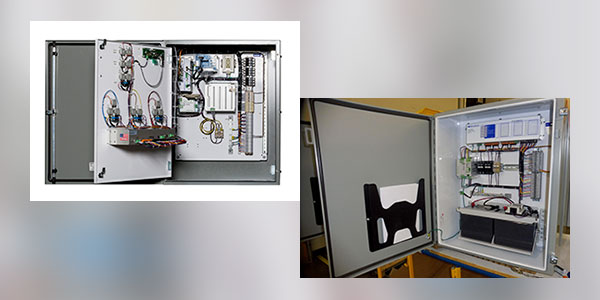

The company uses an Orion integrated communications platform produced by NovaTech Automation, a leading power automation provider for over 35 years who engineers solutions from their Lenexa, Kansas facility. The platform accesses and distributes SCADA, protection and other operational data to quickly identify and resolve problems. It supports Conitel, DNP, IP, Modbus, serial, ST fiber and I/O ports.

States the technician, “Because we program a wide range of devices across a variety of relays and meters, having a single platform to program now makes it so much easier for our field team.”

The power company uses the OrionLX platform for their transmission stations and the smaller OrionLXm for their distribution stations and SCADA controls at some of their power plants and remote switching sites.

According to the technician, the power company initially trialed the Orion platform in a transmission station, after which they have added more units as they upgraded or built new switchyards. The power technician estimates that they now have over 50 units in their transmission stations and about 70 more in their distribution stations.

For more information on substation automation platforms and the Orion family of solutions, visit the NovaTech website at: www.novatechweb.com.