Latest advancements in RTU design enables simplified retrofit of legacy D20, ACS, Systems Northwest, Telvent and other RTU brands without replacing existing wiring

For decades, Remote Terminal Units (RTUs) have been utilized in substations to monitor circuit breaker positions, alarms, voltages/currents, temperature and other data from a variety of wired sensors, or to control breakers, tap changers, and capacitor banks. These remote, real-time data enabled operators to perform supervisory control and data acquisition functions remotely.

However, with the earliest RTU implementations dating back to the late 1970’s, many legacy systems are no longer supported by the original manufacturers and spare parts can be difficult to acquire. In addition, continued advancements in the processing power and control capabilities of modern RTUs mean these units can often eliminate additional boxes, such as HMIs, Alarm Annunciators, Security Gateways, Logic Controllers and Communications Processors.

As a result, transmission and distribution substations that rely heavily on legacy RTUs are ripe for upgrade. Unfortunately, the task traditionally meant not only replacing the RTUs, but also disconnecting and reconnecting hundreds of wires to monitored and controlled devices.

“Even medium-sized distribution substations can have 200-300 I/O points that need to be monitored by RTUs,” according to Ray Wright, VP of Product Management at NovaTech, a leading provider of substation automation solutions. “The larger transmission substations can have well over 1000, so the magnitude of an RTU retrofit can be significant.”

In response, leading substation automation manufacturers have developed retrofit solutions that allow the replacement of legacy RTUs with modern alternatives without the need for re-wiring.

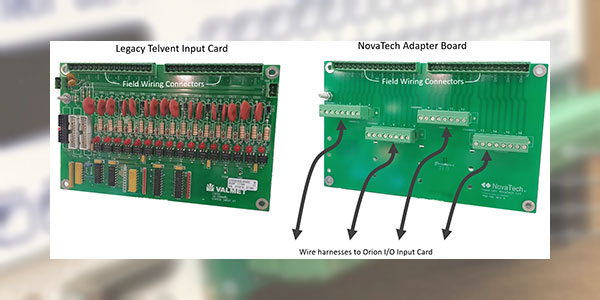

One innovative solution from NovaTech allows for the replacement of legacy RTUs – including D20, Telegy, ACS, Systems Northwest and Telvent – with adaptor boards in the place of the legacy I/O. These adapter boards are connected to the company’s Orion I/O unit through pre-designed wire harnesses. The adaptor boards are designed so the pre-existing wire connectors from the legacy system can be removed and installed while keeping all the wiring intact.

“In most cases, the field wiring is not hardwired to the legacy I/O board,” explains Wright. “Instead, it is wired through a removable connector, which can be lifted and reconnected to the adapter board. The adaptor boards are typically designed to accommodate all of the connectors for the legacy discrete input, discrete output, analog input, and combination cards.”

In situations where field wiring cannot be removed, a “top hat” approach can be used. The top hat is a NovaTech board that is placed on top of the legacy I/O card, connecting to the I/O signal pins. These pins would normally be connected to the legacy RTU, but in retrofits is connected to the Orion RTU.

A slight modification of the above approaches is used for D20 retrofits. The D20 I/O uses four connector styles, two of which – the Phoenix-style terminal and the DB25-style – can be removed from the legacy I/O modules. In such retrofits, by using the same panel space, the process is simplified.

For more information about NovaTech and the Orion family of substation automation solutions visit www.novatechweb.com or call (913) 451-1880.